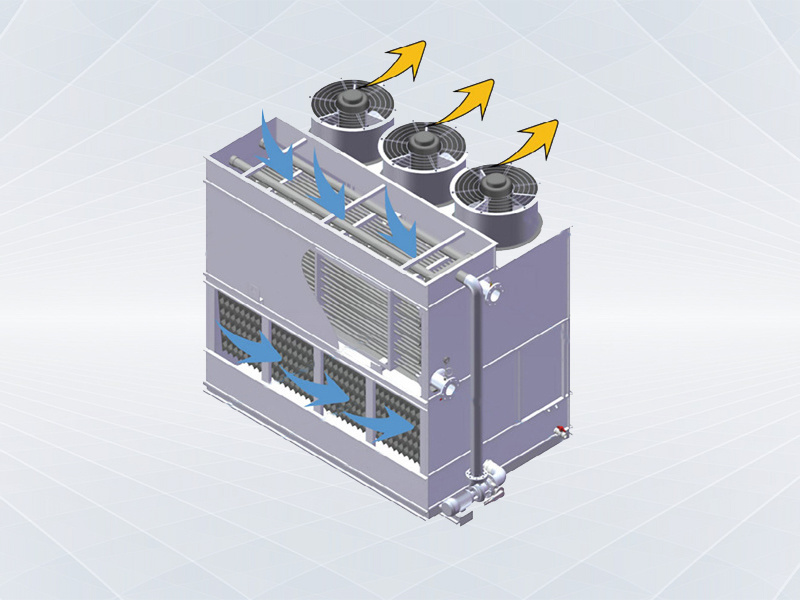

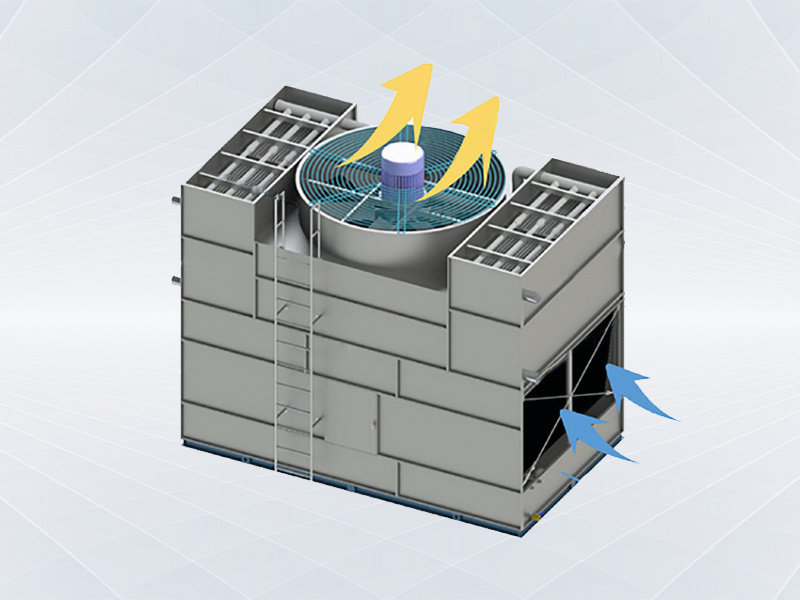

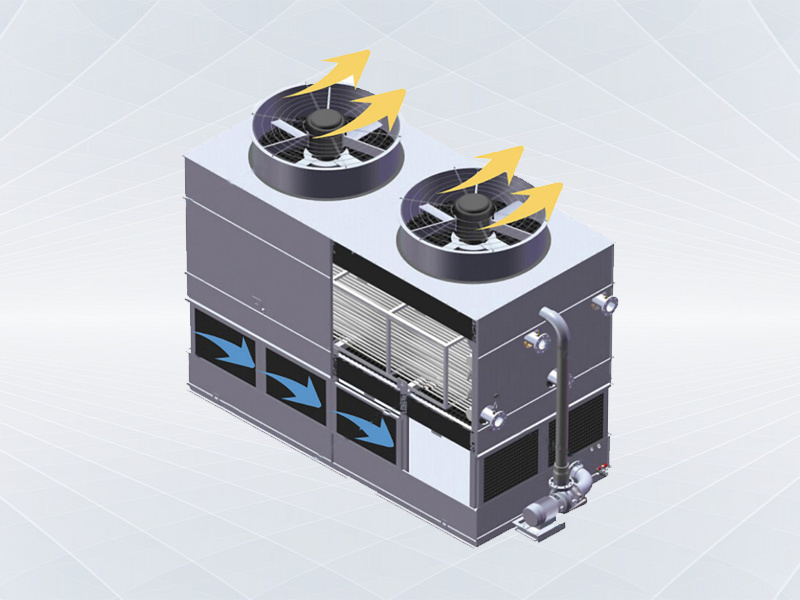

XLKH square cross-flow open cooling tower

Summary

Keywords:Closed cooling tower / Sealed cooling tower / Enclosed cooling tower

Product details

Product performance

1, In the high temperature difference (HIGHRANGE), that is, hot water cold water temperature difference of more than 18 degrees, because the hot water to reduce the temperature in a short period of time more than 18 degrees, need to have sufficient time and filler air contact, so the filler to do very high. (actually equivalent to two, three times cooling);

2. Since the wind and water of the cross-flow tower are cross-flowing, the resistance is only related to the radial depth, and has nothing to do with the height, so it can be achieved very high in theory;

3, and the countercurrent tower packing can not be done very high, wind and water convection, generally do more than 1.5M, it may produce air resistance. For example, the color coating and galvanizing cooling of steel mills, rubber plants, hot water needs to be reduced from 55 degrees to 35 degrees or less, you can use cross-flow towers;

4, SKS steel made of water tower, packing height 5.5M, cooling temperature difference of 25 degrees; For the paper production process of APP Sinar Mas Group, using 400T/H single CELL cross-flow tower, packing height 15M;

5. In sewage occasions, the cross-flow tower can use grid materials, and can be convenient for purification at any time, without downtime; Although the counterflow tower can use grid packing, there is a problem with the principle, and in the actual project, the sewage is often accompanied by high temperatures, so the cross-flow tower can be used in two prongs.

XLKH Square Cross-Flow Open Cooling Tower Parameter Table

| Parameter/water volume m3/h/model | Standard type | Dimensions | Air | Wind blade diameter | Motor power | Into the tower Head | Open tower interface pipe diameter | weight | Noise value | ||||||

| 37~32℃ | Long (L) | Width (W) | High (H) | Inlet and outlet water | Overflow | Sewage | Hydrate | dead weight | run | Standard points | |||||

| 28℃ | mm | mm | mm | ㎡3/h | mm | KW | mH2O | DNmm | DNmm | DNmm | DNmm | Kg | Kg | DN | |

| XLKH-50 | 50 | 1500 | 3200 | 3200 | 33000 | 1200 | 1.5 | 3.8 | 100 | 50 | 40 | 20 | 670 | 1475 | 58 |

| XLKH-65 | 65 | 1880 | 3200 | 3200 | 40000 | 1200 | 2.2 | 3.8 | 100 | 50 | 40 | 20 | 740 | 1685 | 58 |

| XLKH-80 | 80 | 1880 | 3400 | 3200 | 56000 | 1500 | 3 | 3.8 | 125 | 65 | 40 | 20 | 8802 | 2040 | 59 |

| XLKH-100 | 100 | 2180 | 3400 | 3700 | 60000 | 1500 | 3 | 4.2 | 125 | 65 | 40 | 20 | 1150 | 2350 | 59 |

| XLKH-125 | 125 | 2180 | 3800 | 3700 | 79000 | 1800 | 4 | 4.2 | 150 | 80 | 40 | 20 | 1250 | 2550 | 59 |

| XLKH-150 | 150 | 2680 | 3800 | 3700 | 100000 | 1800 | 4 | 4.2 | 150 | 80 | 40 | 20 | 1350 | 2850 | 59 |

| XLKH-175 | 175 | 2680 | 4200 | 3700 | 105000 | 2200 | 5.5 | 4.2 | 200 | 80 | 40 | 20 | 1520 | 3130 | 60 |

| XLKH-200 | 200 | 2680 | 4200 | 4500 | 125000 | 2200 | 7.5 | 5.1 | 200 | 80 | 40 | 25 | 1620 | 3770 | 60 |

| XLKH-225 | 225 | 3000 | 4200 | 4500 | 130000 | 2200 | 7.5 | 5.1 | 200 | 80 | 40 | 25 | 2080 | 4300 | 60 |

| XLKH-250 | 250 | 3000 | 4500 | 4500 | 175000 | 2500 | 7.5 | 5.1 | 200 | 80 | 40 | 25 | 2200 | 4870 | 61 |

| XLKH-300 | 300 | 3000 | 5000 | 4500 | 185000 | 2500 | 7.5 | 5.1 | 200 | 80 | 40 | 25 | 2550 | 5300 | 61 |

| XLKH-350 | 350 | 3300 | 5500 | 4800 | 200000 | 2950 | 11 | 5.4 | 250 | 80 | 40 | 40 | 2850 | 6200 | 61 |

| XLKH-400 | 400 | 3300 | 5500 | 5400 | 220000 | 2950 | 11 | 6 | 250 | 80 | 40 | 40 | 3250 | 6600 | 62 |

| XLKH-450 | 450 | 3800 | 5550 | 5400 | 235000 | 2950 | 11 | 6 | 250 | 80 | 50 | 40 | 3550 | 7400 | 62 |

| XLKH-500 | 500 | 3800 | 6000 | 5600 | 305000 | 3400 | 15 | 6.2 | 300 | 80 | 50 | 40 | 4050 | 8200 | 63 |

| XLKH-600 | 600 | 4600 | 6000 | 5600 | 335000 | 3400 | 15 | 6.2 | 300 | 80 | 50 | 50 | 4650 | 9800 | 63 |

| XLKH-700 | 700 | 4600 | 6200 | 6000 | 395000 | 3600 | 18.5 | 6.5 | 300 | 80 | 50 | 50 | 5050 | 10500 | 64 |

| XLKH-800 | 800 | 5100 | 6200 | 6000 | 455000 | 3600 | 22 | 6.5 | 300 | 80 | 50 | 50 | 5450 | 115000 | 65 |

Note: The parameter changes caused by the modification of the equipment are subject to no prior notice, and the specific parameters are mainly based on our program. Steel open tower, parameters are queried.

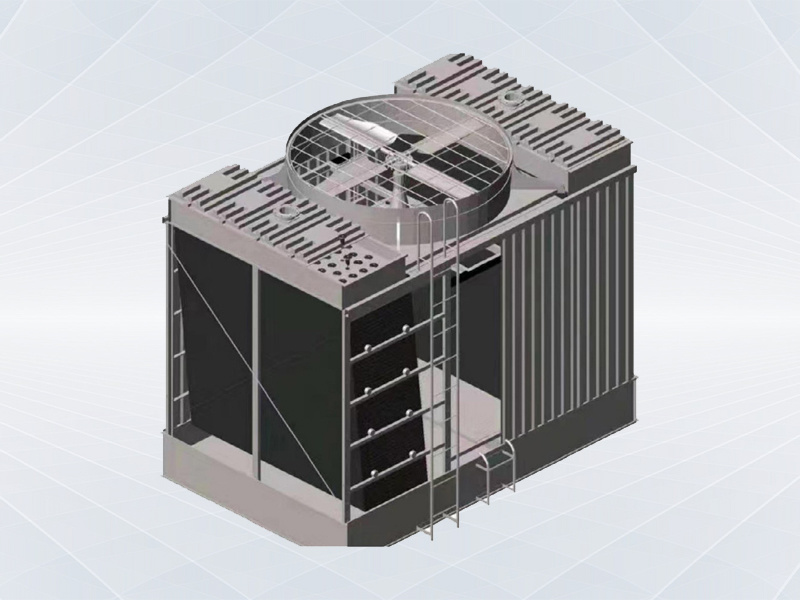

Related Products

Landline

Address

No. 16, Baishijian Road, Langxi Industrial Park, Anhui Province

©2022 Anhui XILENG Environmental Protection Technology Co., Ltd Powered by www.300.cn Seo